Australian researchers have created building blocks out of DNA to construct a series of nano-scale objects and shapes, from a rod and a square to an infinitesimally small dinosaur.

The approach turns DNA into a modular material for building nanostructures – thousands of times narrower than a human hair. Developed by researchers from the University of Sydney Nano Institute and published in the journal Science Robotics, it suggests exciting possibilities for future use of nanobot technology.

As a proof-of-concept, the authors made more than 50 tiny shapes to test their precision and express their creativity. These included a dragon, a dinosaur, and a tiny map of Australia measuring only 150 nanometres wide. (A nanometre is one millionth of a millimetre.)

University of Sydney scientist Dr Shelley Wickham, co-author of the paper and research team leader, said the dinosaur was her favourite because it had both compact and flexible parts and was “not something that could assemble by accident”.

The director of RMIT’s micro nano research facility, Prof Arnan Mitchell, who was not involved with the paper, noted that the approach relied on using DNA as a mechanical object rather than as a chemical. This was interesting, he said, because structures made from DNA were potentially small enough to be used in drug delivery.

DNA could be wrapped around a drug to protect it for delivery to a particular part of the body, he said. “Deliver it to where it needs to go, and then use light or heat or something else to make it unfurl and release the drug.”

With increased complexity and greater control, Wickham said the researchers’ approach could be used to make components for robotic boxes capable of delivering targeted drugs, or in the development of smart materials that could respond to the environment.

“This work enables us to imagine a world where nanobots can get to work on a huge range of tasks, from treating the human body to building futuristic electronic devices.”

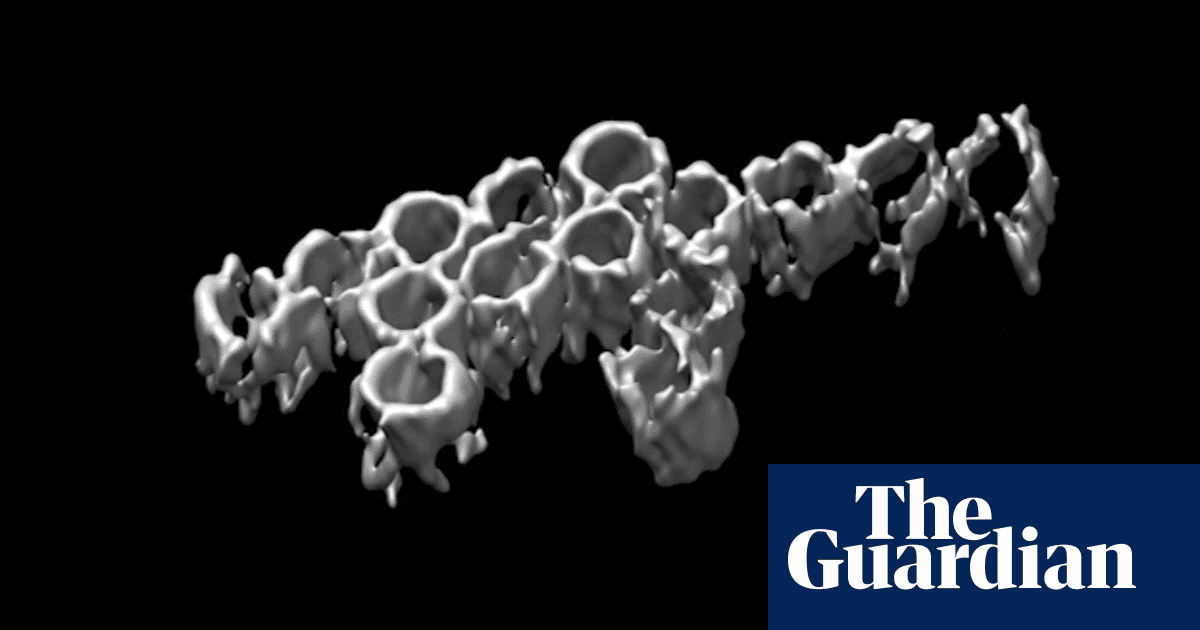

Wickham outlined the process. The first step involved making the 3D building blocks, called “voxels”, she said. DNA, extracted from a type of virus called a bacteriophage, was “folded” into a cylindrical shape using an approach called DNA origami and held together with synthetic DNA (made by chemists).

Voxels were formed by self-assembly, Wickham explained, relying on carefully sequenced DNA binding together at pre-determined locations, a bit like velcro or specialised glue.

“We throw in 300 of these staples that all have a unique DNA sequence – like a unique glue – and they find different parts of the scaffold and stitch it together,” she said.

Additional DNA strands incorporated on to the exterior of the voxels, acted as programmable binding sites. These could be used to join voxels together to construct more complex shapes and modular objects, which could be viewed under an electron microscope.

“The results are a bit like using Meccano, the children’s engineering toy,” Wickham said. “As experimentalists, we spent a lot of time designing these on computers. And then we take the DNA and mix it together and it assembles itself.”